Downhole Chemical Injection Lines-Gịnị kpatara Ha ji ada?Ahụmahụ, ihe ịma aka na ntinye nke ụzọ nnwale ọhụrụ

Nwebiisinka 2012, Society of Petroleum Engineers

Abstract

Statoil na-arụ ọrụ n'ọtụtụ ebe ebe a na-etinye ọgwụ mgbochi na-aga n'ihu nke downhole.Ebumnuche bụ ichebe tubing elu na valvụ nchekwa site na (Ba/Sr) SO4orCaCO;ọnụ ọgụgụ, n'ọnọdụ ebe ọnụ ọgụgụ squeezing nwere ike isiri ike na ọnụ ahịa ịrụ kwa mgbe, eg tie-in nke subsea ubi.

Ịgba ogwu na-aga n'ihu nke onye na-eme ihe na-eme ka ọkpụkpụ na-eme ka ọ bụrụ ihe ngwọta nke nkà na ụzụ kwesịrị ekwesị iji chebe tubing elu na valvụ nchekwa na olulu mmiri nke nwere ike ịka elu n'elu ihe mmepụta ihe;karịsịa n'ime olulu mmiri na-adịghị mkpa ka a na-amanye ya mgbe niile n'ihi ike na-eme ka ọ dị na mpaghara olulu mmiri dị nso.

Ịmepụta, ịrụ ọrụ na idowe ahịrị injection kemịkalụ chọrọ itinyekwu uche na nhọrọ ihe, ntozu kemịkalụ na nleba anya.Nrụgide, ọnọdụ okpomọkụ, usoro mgbaba na geometry nke sistemu nwere ike webata ihe ịma aka maka ịrụ ọrụ nchekwa.Achọpụtala ihe ịma aka n'ahịrị ịgba ọgwụ ogologo nke dị ọtụtụ kilomita site na ebe a na-emepụta ihe ruo na template subsea yana na valves injection gbadara n'olulu mmiri.

Ahụmahụ ubi na-egosi mgbagwoju anya nke sistemu ịgba ọgwụ na-aga n'ihu na-aga n'ihu gbasara mmiri ozuzo na okwu corrosion.Nnyocha ụlọ nyocha na itinye usoro ọhụrụ maka ntozu kemịkalụ a nọchitere anya.A na-edozi mkpa maka omume multidisciplinary.

Okwu mmalite

Statoil na-arụ ọrụ n'ọtụtụ ebe ebe etinyere ọgwụ kemịkalụ na-aga n'ihu.Nke a na-agụnyekarị injection nke ihe mgbochi ọnụ ọgụgụ (SI) ebe ebumnuche bụ iji chebe tubing elu na valvụ nchekwa ala (DHSV) site na (Ba / Sr) SO4orCaCO;ọnụ ọgụgụ.N'ọnọdụ ụfọdụ, a na-agbanye emulsion breaker downhole ka ịmalite usoro nkewa dị omimi n'ime olulu mmiri dị ka o kwere mee na oke okpomọkụ.

Ịgba ogwu na-aga n'ihu nke ihe na-egbochi ihe nrịbama downhole bụ ihe ngwọta kwesịrị ekwesị na teknụzụ iji chebe akụkụ elu nke olulu mmiri ndị nwere ike ịcha elu karịa ihe nrụpụta mmepụta.Enwere ike ịkwado injection na-aga n'ihu karịsịa n'ime olulu mmiri ndị na-adịghị mkpa ka a kpachie ya n'ihi ike dị ntakịrị na olulu mmiri dị nso;ma ọ bụ n'ọnọdụ ebe mkpọka ọnụ ọgụgụ nwere ike isi ike ma dị oke ọnụ ịme oge niile, dịka tie-in nke mpaghara oke osimiri.

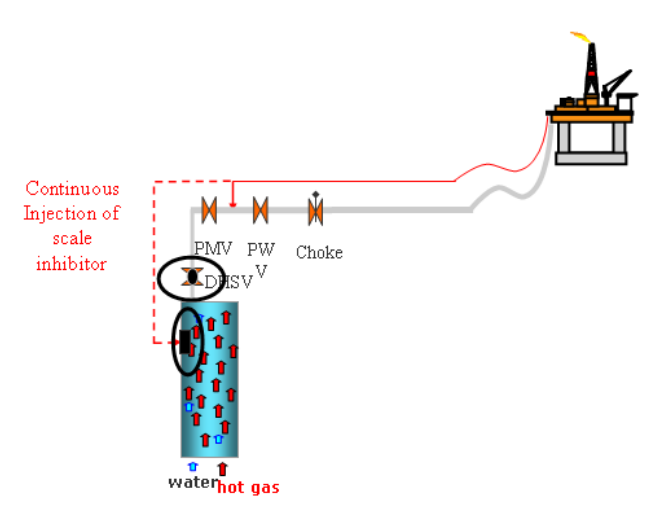

Statoil agbatịla ahụmịhe na ịgbanye kemịkalụ na-aga n'ihu na sistemu dị n'akụkụ yana ndebiri subsea mana ihe ịma aka ọhụrụ bụ iburu ebe ntụtụ ahụ banye n'ime olulu mmiri ahụ.Ịmepụta, ịrụ ọrụ na idowe ahịrị injection kemịkalụ chọrọ itinyekwu uche n'ọtụtụ isiokwu;dị ka nhọrọ ihe, kemịkalụ iru eru na nlekota oru.Nrụgide, ọnọdụ okpomọkụ, usoro mgbaba na geometry nke sistemu nwere ike webata ihe ịma aka maka ịrụ ọrụ nchekwa.Achọpụtara ihe ịma aka dị n'ahịrị injection ogologo (ọtụtụ kilomita) site na mmepụta ihe ruo na template subsea na n'ime valves injection gbadara n'olulu mmiri;Fig.1.Ụfọdụ usoro ịgba ọgwụ na-arụ ọrụ dịka atụmatụ siri dị, ebe ndị ọzọ dara n'ihi ihe dị iche iche.Ọtụtụ ọhụrụ ubi mmepe na-zubere maka downhole chemical injection (DHCI);otu o sila dị;N'ọnọdụ ụfọdụ akụrụngwa erubeghị nke ọma ma.

Ngwa nke DHCI bụ ọrụ dị mgbagwoju anya.Ọ na-agụnye mmecha na nhazi nke ọma, kemịkalụ nke ọma, usoro topside na usoro usoro onunu ogwu nke usoro topside.A ga-esi n'elu wụpụ kemịkalụ ahụ site n'ahịrị injection kemịkalụ gaa na akụrụngwa arụcha ma gbadaa n'olulu mmiri ahụ.N'ihi ya, na nhazi na mmezu nke ụdị nkwado a n'etiti ọtụtụ ọzụzụ dị oke mkpa.A ghaghị ịtụle echiche dị iche iche na nkwurịta okwu dị mma n'oge imewe dị mkpa.Ndị injinia usoro, ndị injinia subsea na ndị injinia mmecha na-etinye aka, na-emekọ isiokwu nke kemịkalụ nke ọma, nhọrọ ihe, mmesi obi ike na njikwa kemịkalụ mmepụta.Ihe ịma aka ndị a nwere ike ịbụ eze egbe kemịkal ma ọ bụ nkwụsi ike okpomọkụ, corrosion na mgbe ụfọdụ mmetụta agụụ n'ihi nrụgide mpaghara na mmetụta eruba na ahịrị injection kemịkal.Na mgbakwunye na ihe ndị a, ọnọdụ ndị dị ka nrụgide dị elu, okpomọkụ dị elu, ọnụ ọgụgụ gas dị elu, ikike dị elu,ogologo eriri afọ na omimi injection n'ime olulu mmiri, na-enye ihe ịma aka nka dị iche iche na ihe achọrọ maka kemịkalụ ịgbanye na valvụ injection.

Ntụle nke usoro DHCI arụnyere na arụ ọrụ Statoil na-egosi na ahụmahụ ahụ adịghị eme nke ọma mgbe niile Tebụl 1. Otú ọ dị, a na-eme atụmatụ maka imeziwanye nhazi nke injection, iru eru kemịkal, ọrụ na mmezi.Ihe ịma aka ndị ahụ dịgasị iche site n'ubi ruo ubi, nsogbu ahụ abụghịkwa na valvụ injection kemịkal n'onwe ya adịghị arụ ọrụ.

N'ime afọ gara aga, enwere ọtụtụ nsogbu gbasara ahịrị injection kemịkalụ downhole.N'ime akwụkwọ a ka e nyere ọmụmaatụ ụfọdụ site na ahụmahụ ndị a.Akwụkwọ a na-atụle ihe ịma aka na usoro e mere iji dozie nsogbu ndị metụtara ahịrị DHCI.E nyere akụkọ ikpe abụọ;otu na corrosion na otu na chemical egbe eze.Ahụmahụ ubi na-egosi mgbagwoju anya nke sistemu ịgba ọgwụ na-aga n'ihu na-aga n'ihu gbasara mmiri ozuzo na okwu corrosion.

A na-atụlekwa ọmụmụ ụlọ nyocha na itinye usoro ọhụrụ maka ntozu kemịkalụ;otu esi agbapu kemịkalụ ahụ, ikike ịbelata na mgbochi, ngwa akụrụngwa dị mgbagwoju anya yana etu kemịkalụ ga-esi metụta sistemu dị n'akụkụ mgbe a na-emepụta kemịkalụ azụ.Nabata njirisi maka ngwa kemịkalụ gụnyere nsogbu gburugburu ebe obibi, arụmọrụ, ikike nchekwa n'elu, ọnụego mgbapụta, ma enwere ike iji mgbapụta dị ugbu a wdg. Nkà na ụzụ na-atụ aro ga-dabere n'elu ndakọrịta mmiri na kemịkalụ, nchọpụta mpụta, ndakọrịta ihe, imewe eriri mmiri, sistemu ọgwụ kemịkalụ. na ihe ndị dị na gburugburu ahịrị ndị a.Enwere ike igbochi kemịkalụ hydrate iji gbochie nkwụnye nke ahịrị ịgba ọgwụ site na mbuso agha gas na kemịkalụ agaghị ajụ oyi n'oge njem na nchekwa.N'ime ntuziaka dị n'ime, enwere ndepụta nyocha nke enwere ike itinye kemịkalụ n'oge ọ bụla na sistemụ Njirimara anụ ahụ dị ka viscosity dị mkpa.Sistemu ịgba ọgwụ nwere ike ịpụta 3-50km nke eriri eriri afọ n'okpuru osimiri na 1-3km gbadaa n'olulu mmiri.N'ihi ya, nkwụsi ike okpomọkụ dịkwa mkpa.Nlele nke downstream mmetụta, eg na refineries nwekwara ike ga-atụle.

Sistemụ injection kemịkalụ Downhole

Ọnụ ego

Na-aga n'ihu ntụtụ nke ihe mgbochi ọnụ ọgụgụ na-agbada iji chebe DHS Vor tubing mmepụta nwere ike ọ dị irè ma e jiri ya tụnyere iji ihe mgbochi ọnụ na-amanye olulu mmiri.Ngwa a na-ebelata ohere nke ịmepụta mmebi ma e jiri ya tụnyere ọgwụgwọ piakọta ọnụ ọgụgụ, na-ebelata ikike nke usoro nsogbu mgbe ọnụ ọgụgụ squeezes gasịrị ma na-enye ohere iji chịkwaa ọnụego injection kemịkalụ site na usoro injection topside.Enwere ike iji usoro ịgba ọgwụ ahụ wee gbanye kemịkalụ ndị ọzọ na-agbadata n'ihu wee si otú a belata ihe ịma aka ndị ọzọ nwere ike ịdaba n'ihu n'ime ụlọ ọrụ.

Emeela ọmụmụ ihe zuru oke na-emepụta atụmatụ mgbada ala nke Oseberg S ma ọ bụ ubi.Ihe kachasị mkpa bụ CaCO;scaling na tubing elu yana ọdịda DHSV ga-ekwe omume.Atụmatụ njikwa usoro Oseberg S ma ọ bụ ọnụ ọgụgụ kwubiri na n'ime afọ atọ, DHCI bụ ihe ngwọta kachasị ọnụ nke ọma na olulu mmiri ebe ahịrị injection kemịkal na-arụ ọrụ.Isi ihe na-eri n'ihe gbasara usoro ịsọ mpi nke nha nha bụ mmanụ ewegharịrị karịa ọnụahịa kemịkalụ/ọrụ.Maka ngwa nke ihe mgbochi ọnụ ọgụgụ na ebuli gas, isi ihe na-eri kemịkalụ bụ elu gas ebuli elu ọnụego na-eduga na elu SI ịta, ebe ọ bụ na ịta ahụhụ ga-nguzozi na gas ebuli ọnụego iji zere chemical egbe eze.Maka olulu mmiri abụọ dị na Oseberg S ma ọ bụ nke nwere ahịrị DHC I na-arụ ọrụ nke ọma, a họọrọ nhọrọ a iji chebe DHS V megide CaCO;akpịrịkpa.

Usoro injection na-aga n'ihu na valves

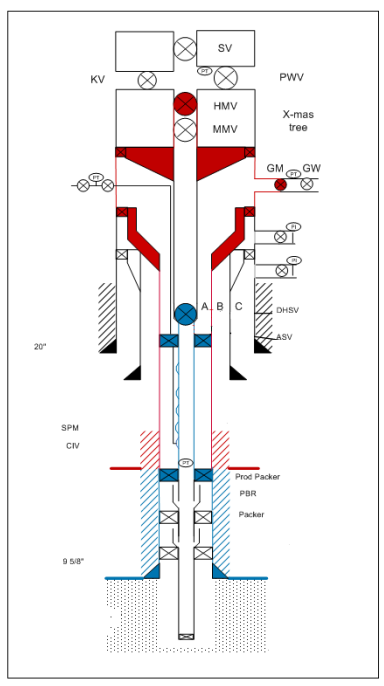

Ngwọta mmecha dị adị site na iji sistemu injection kemịkalụ na-aga n'ihu na-eche ihe ịma aka ihu iji gbochie nkwụnye nke ahịrị capillary.Na-emekarị usoro ịgba ọgwụ ahụ nwere eriri capillary, 1/4 "ma ọ bụ 3/8" n'èzí dayameta (OD), jikọtara ya na elu elu, na-eri nri na-ma jikọọ ya na onye na-ekpuchi tub n'akụkụ akụkụ nke tubing.A na-ejikọta eriri capillary na dayameta dị n'èzí nke tubing mmepụta site na tubing collars pụrụ iche ma na-agba ọsọ n'èzí nke tubing ruo n'ókè nke kemịkalụ injection mandrel.A na-edobe mandrel ahụ n'ọdịnala-iyi nke DHS V ma ọ bụ miri emi n'ime olulu mmiri n'ebumnobi nke inye kemịkalụ ịgbanye oge mgbasa ozi zuru oke yana idowe kemịkalụ ebe a na-ahụ ihe ịma aka.

Na valvụ injection kemịkalụ, Fig.2, obere katrij dị ihe dị ka 1.5 "na dayameta nwere valvụ nlele nke na-egbochi mmiri mmiri nke ọma ịbanye n'ahịrị capillary.Ọ bụ naanị obere poppet na-agba n'elu mmiri.Ike mmiri na-esetịpụ ma buru amụma nrụgide chọrọ imeghe poppet ahụ n'oche mkpuchi.Mgbe kemịkalụ malitere ịgba, a na-ebuli poppet ahụ n'oche ya wee mepee valvụ nlele.

Ọ chọrọ ka etinyere valvụ nlele abụọ.Otu valvụ bụ ihe mgbochi bụ isi na-egbochi mmiri mmiri nke ọma ịbanye n'ahịrị capillary.Nke a nwere nrụgide mmeghe dị ntakịrị (2-15bars) .Ọ bụrụ na nrụgide hydrostatic n'ime eriri capillary dị ntakịrị karịa nrụgide olulu mmiri, mmiri mmiri na-agba mmiri ga-agbalị ịbanye n'ime eriri capillary.valvụ nlele ọzọ nwere nrụgide mmeghe nke 130-250 ma mara ya dị ka usoro mgbochi U-tube.valvụ a na-egbochi kemịkalụ dị n'ime eriri capillary ka ọ banye n'ime olulu mmiri ma ọ bụrụ na nrụgide hydrostatic dị n'ime eriri capillary dị ukwuu karịa nrụgide olulu mmiri na ebe injection kemịkalụ n'ime tubing mmepụta.

Na mgbakwunye na valvụ nlele abụọ ahụ, a na-enwekarị ihe nzacha inline, ebumnuche nke a bụ iji hụ na ọ nweghị ihe irighiri ihe ọ bụla nwere ike imebi ikike akara nke sistemu valvụ nlele.

Ogo nke valvụ nlele akọwara dị ntakịrị, na ịdị ọcha nke mmiri ịgbanye dị mkpa maka ịrụ ọrụ ha.A kwenyere na a ga-ekpochapụ irighiri ihe ndị dị na sistemụ ahụ site n'ịbawanye ụba nke n'ime eriri capillary, nke mere na valvụ nlele na-ama ụma meghee.

Mgbe valvụ nlele meghere, nrụgide na-erugharị na-agbada ngwa ngwa ma gbasaa ahịrị capillary ruo mgbe nrụgide na-abawanye ọzọ.valvụ nlele ahụ ga-emechi ruo mgbe mmiri nke kemịkalụ na-ewulite nrụgide zuru oke iji mepee valvụ ahụ;Ihe si na ya pụta bụ oscillation nrụgide na usoro valvụ nlele.Nrụgide mmeghe dị elu nke usoro valvụ nlele nwere, a na-emebe ebe a na-eru ala mgbe valvụ nlele meghere na usoro ahụ na-agbalị ime ka ọnọdụ nha anya.

The kemịkalụ injection valves nwere obere mmeghe oghere;na ọ bụrụ na nrụgide tubing na ebe ntinye kemịkalụ na-adị ala karịa nchikota nke hydrostatic mgbali nke kemịkalụ n'ime eriri capillary gbakwunyere nrụgide oghere valve, nso oghere ma ọ bụ oghere ga-eme na akụkụ elu nke eriri capillary.Mgbe ntụtụ kemịkalụ kwụsịrị ma ọ bụ mmiri kemịkalụ dị ala, nso ọnọdụ agụụ ga-amalite ime n'akụkụ elu nke ahịrị capillary.

Ọkwa nke agụụ na-adabere na nrụgide olulu mmiri, kpọmkwem ike ndọda nke ngwakọta kemịkalụ injected a na-eji n'ime eriri capillary, nrụgide oghere valvụ na-agbanye n'ebe injection na mmiri nke kemịkalụ n'ime eriri capillary.Ọnọdụ olulu mmiri ga-adịgasị iche n'ogologo ndụ ubi yana ikike ime oghere ga-adịkwa iche n'oge ọrụ.Ọ dị mkpa ịmara maka ọnọdụ a ka ị were nlezianya na nlezianya kpachara anya tupu nsogbu ndị a tụrụ anya eme.

Yana ọnụ ọgụgụ injections dị ala, ọ na-abụkarị ihe mgbaze a na-eji n'ụdị ngwa ndị a na-ekupụ na-akpata mmetụta na-enyochabeghị nke ọma.Mmetụta ndị a bụ eze egbe ma ọ bụ mmiri ozuzo nke ihe siri ike, dịka ọmụmaatụ polymers, mgbe ihe mgbaze na-ekpochapụ.

Ọzọkwa, enwere ike ịmepụta mkpụrụ ndụ galvanic n'oge mgbanwe n'etiti ikuku mmiri nke kemịkalụ na uzuoku jupụtara nso-agụụ gas na-aga n'elu.Nke a nwere ike ibute corrosion mpaghara n'ime ahịrị capillary n'ihi mmụba nke kemịkalụ n'okpuru ọnọdụ ndị a.Flakes ma ọ bụ kristal nnu kpụrụ dị ka ihe nkiri n'ime ahịrị capillary ka ime ya na-akpọnwụ nwere ike ịgbachi ma ọ bụ gbanye eriri capillary.

Ọfọn ihe mgbochi philosophy

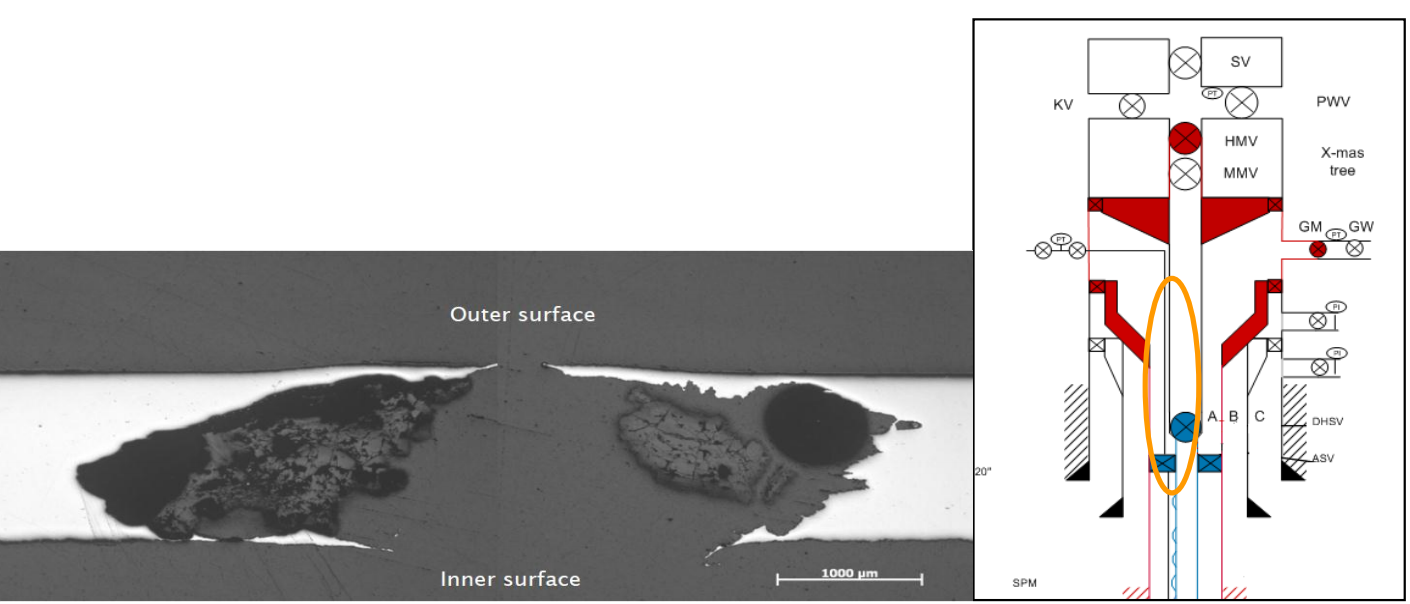

Mgbe ị na-emepụta ihe ngwọta olulu mmiri siri ike, Statoil chọrọ ka nchekwa olulu mmiri dị n'oge ọ bụla n'oge ndụ nke olulu mmiri ahụ.Yabụ, Statoil chọrọ ka enwere ihe mgbochi olulu mmiri abụọ nọọrọ onwe ha.Fig. 3 na-egosi atypical ọma mgbochi schematic, ebe-acha anụnụ anụnụ na agba na-anọchi anya isi ọma mgbochi envelopu;na nke a na mmepụta tubing.Agba uhie na-anọchi anya envelopu mgbochi nke abụọ;ihe mkpuchi ahụ.N'akụkụ aka ekpe na eserese ahụ, a na-egosi injection kemịkal dị ka eriri ojii nwere ntụ ntụ maka tubing mmepụta na mpaghara akara uhie (ihe mgbochi nke abụọ).Site n'iwebata usoro ịgba ọgwụ mgbochi mmiri n'ime olulu mmiri, ma ihe mgbochi nke isi na nke abụọ na-emebi.

Akụkọ ikpe gbasara corrosion

Usoro nke ihe omume

E tinyela ọgwụ ogbugba ogbunigwe nke Downhole n'ime ebe mmanụ Statoil na-arụ na shelf Continental Norwegian.N'okwu a, ihe mgbochi nha nke etinyere na mbụ eruola maka ngwa topside na subsea.Emechara nke ọma site na ntinye nke DHCIpointat2446mMD, Fig.3.A malitere ịgbanye mgbada ala nke ihe mgbochi ọnụ ọgụgụ elu na-enweghị nyocha ọzọ nke kemịkal.

Mgbe otu afọ nke ọrụ gasịrị, a hụrụ n'ime sistemu ịgba ọgwụ mgbochi ọrịa wee malite nyocha.Mwepu ahụ nwere mmetụta na-emebi emebi na ihe mgbochi olulu mmiri.Ihe ndị yiri nke ahụ mere maka ọtụtụ olulu mmiri na ụfọdụ n'ime ha ga-emechi mgbe nyocha na-aga n'ihu.

A dọtara tubing mmepụta ma mụọ n'ụzọ zuru ezu.Mwakpo corrosion bụ nanị otu akụkụ nke tubing ahụ, na ụfọdụ nkwonkwo tubing mebiri emebi nke na enwere oghere site na ha.Ihe dị ka 8.5mm gbara ọkpụrụkpụ 3% chrome emebiwo n'ihe na-erughị ọnwa 8.Isi corrosion mere na akụkụ elu nke olulu mmiri ahụ, site na olulu mmiri ruo ihe dịka 380m MD, na nkwonkwo tubing kachasị njọ bụ ihe dị ka 350m MD.N'okpuru omimi a, ahụrụ ntakịrị ma ọ bụ enweghị corrosion, mana ahụrụ ọtụtụ irighiri ihe na tubing OD's.

A na-egbutukwa ihe mkpuchi 9-5 / 8'' ma dọpụta ya na mmetụta ndị yiri ya;na corrosion na akụkụ elu nke olulu mmiri n'otu akụkụ naanị.Ihe kpatara ntapu a kpalitere bụ site n'ịkụwa akụkụ ahụ adịghị ike nke mkpuchi ahụ.

Ihe ahịrị ahịrị ọgwụ bụ Alloy 825.

Ntozu kemịkalụ

Njirimara kemịkalụ na nnwale corrosion bụ ihe dị mkpa na-elekwasị anya na ntozu nke ndị na-egbochi ọnụ ọgụgụ na onye na-egbochi ọnụ ọgụgụ n'ezie tozuru oke ma jiri ya na ngwa topside na subsea ruo ọtụtụ afọ.Ihe mere etinyere n'ezie chemical downhole e mma gburugburu ebe obibi site na-edochi dị downhole chemical Otú ọ dị, ọnụ ọgụgụ inhibitor ka e ji mee ihe na ambient topside na oké osimiri (4-20 ℃).Mgbe etinyere n'ime olulu mmiri ahụ, kemịkalụ ahụ nwere ike ịdị elu ruo 90 ℃, mana enwebeghị nnwale ọzọ emere na okpomọkụ a.

Onye na-eweta kemịkalụ mere nnwale izizi nke corrosivity yana nsonaazụ gosipụtara 2-4mm / afọ maka ígwè carbon na oke okpomọkụ.N'ime usoro a, enweela itinye aka kacha nta na ikike nka nka nke onye ọrụ.Onye na-arụ ọrụ mechara mee ule ọhụrụ na-egosi na onye na-emechi ọnụ ọgụgụ na-emebi emebi nke ukwuu maka ihe ndị dị na tubing mmepụta na mmepụta ihe, na ọnụ ọgụgụ corrosion karịrị 70mm / afọ.A nwalebeghị ahịrị ahịrị ọgwụ kemịkalụ Alloy 825 megide ihe mgbochi nha tupu ịgba ọgwụ.Okpomọkụ nke ọma nwere ike iru 90 ℃ na ule zuru oke kwesịrị ka emere ya n'okpuru ọnọdụ ndị a.

Nnyocha ahụ gosikwara na onye na-egbochi ọnụ ọgụgụ dị ka ngwọta na-etinye uche na-akọ pH nke <3.0.Agbanyeghị, a tụlebeghị pH ahụ.Mgbe e mesịrị, pH tụrụ atụ gosiri ntakịrị uru pH 0-1.Nke a na-egosi mkpa ọ dị maka nha na nleba anya ihe onwunwe na mgbakwunye na ụkpụrụ pH nyere.

Nkọwa nke nsonaazụ

A na-arụ eriri injection (Fig.3) iji nye nrụgide hydrostatic nke onye na-emechi ọnụ ọgụgụ nke na-agafe nrụgide na nke ọma na ebe injection.A na-agbanye onye na-egbochi ya na nrụgide dị elu karịa dị na olulu mmiri.Nke a na-ebute mmetụta U-tube na imechi olulu mmiri.valvụ ahụ ga-emeghe mgbe niile site na nrụgide dị elu na ahịrị injection karịa na olulu mmiri.Ọpụpụ ma ọ bụ evaporation n'ahịrị injection nwere ike ime.Ọnụ ọgụgụ corrosion na ihe ize ndụ nke olulu kacha ukwuu na mpaghara mgbanwe gas / mmiri mmiri n'ihi evaporation nke ihe mgbaze.Nnwale ụlọ nyocha emere na Kupọns kwadoro echiche a.N'ime olulu mmiri ebe a na-ahụ mmiri mmiri, oghere niile dị n'ahịrị injection dị n'akụkụ elu nke eriri ọgwụ ọgwụ.

Fig. 4 na-egosi foto nke ahịrị DHC I nwere nnukwu corrosion corrosion.Nrụrụ ahụ a hụrụ na tubing mmepụta nke dị n'èzí gosipụtara mkpughe nke ihe mgbochi ọnụ ọgụgụ mpaghara site na ebe mgbapu mmiri.Ihe kpatara ntapu a bụ site n'ịkpọba corrosion site na kemịkalụ na-emebi emebi nke ukwuu na mpụta site na ahịrị injection kemịkalụ n'ime ihe mkpuchi mmepụta.A na-efesa ihe mgbochi nke ọnụ ọgụgụ ahụ site na ahịrị capillary olulu ahụ gaa na casing na tubing na ntapu mere.Atụlela nsonaazụ nke abụọ ọ bụla nke ntapu na ahịrị injection ahụ.E kwubiri na casing-na tubing corrosion bụ n'ihi nke ndị na-emechi ọnụ ọgụgụ na-etinye uche na-ekpe ekpere site na ahịrị capillary nke nwere oghere na casing na tubing, Fig.5.

N'okwu a, enwebeghị ike itinye aka na ndị injinia ruru eru.A nwalebeghị mmebi nke kemịkalụ na ahịrị DHCI yana enyochaghị mmetụta nke abụọ n'ihi ntanye;dị ka ma ihe ndị gbara ya gburugburu nwere ike ịnabata mkpughe kemịkal.

Akụkọ ikpe nke eze kemịkalụ-egbe

Usoro nke ihe omume

Atụmatụ mgbochi ọnụ ọgụgụ maka ubi HP HT bụ ịgba ọgwụ mgbochi ọnụ ọgụgụ na-aga n'ihu na valvụ nchekwa ala.Achọpụtara ihe nwere ike ịkpachapụ anya nke calcium carbonate na olulu mmiri ahụ.Otu n'ime ihe ịma aka ndị ahụ bụ oke okpomọkụ na nnukwu gas na ọnụ ọgụgụ mmepụta nke condensate jikọtara ọnụ ọgụgụ mmiri dị ala.Nchegbu site na injecting ọnụ ọgụgụ inhibitor bụ na ihe mgbaze ga-apụ apụ site na elu gas mmepụta ọnụego na egbe eze nke chemical ga-eme na injection point upstream nke nchekwa valvụ na olulu mmiri, Fig.1.

N'oge ntozu nke onye na-emechi ọnụ ọgụgụ, a na-elekwasị anya na arụmọrụ nke ngwaahịa na ọnọdụ HP HT gụnyere omume na usoro usoro topside (obere okpomọkụ).Mmiri ozuzo nke onye na-emechi ọnụ ọgụgụ n'onwe ya na tubing mmepụta n'ihi oke gas dị elu bụ isi nchegbu.Nnwale nyocha ụlọ nyocha gosiri na ihe mgbochi ọnụ ọgụgụ nwere ike ịwụsa ma rapara na mgbidi tubing.Ịrụ valvụ nchekwa nwere ike ime ihe egwu.

Ahụmahụ gosiri na mgbe izu ole na ole arụ ọrụ gasịrị, eriri kemịkal na-agbapụta.Ọ ga-ekwe omume nyochaa nrụgide olulu mmiri na nlele elu nke etinyere na eriri capillary.Ahịrị ahụ dịpụrụ adịpụ iji nweta iguzosi ike n'ezi ihe.

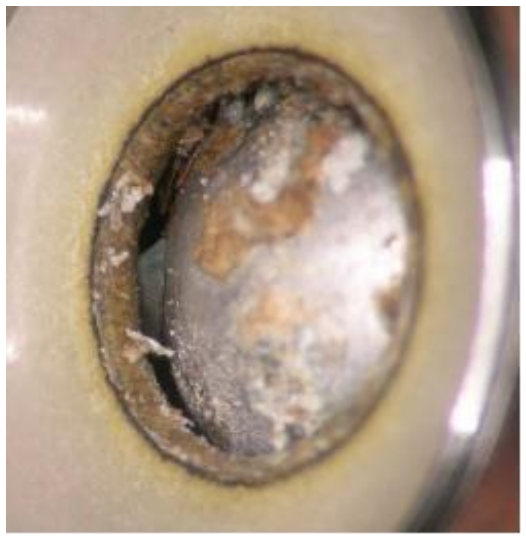

E wepụrụ ahịrị injection kemịkalụ n'olulu mmiri ahụ, meghee wee lelee ya iji chọpụta nsogbu ahụ wee chọpụta ihe kpatara ọdịda.Dị ka a na-ahụ na Fig.6, a chọtara nnukwu mmiri ozuzo na nyocha nke kemịkal gosiri na ụfọdụ n'ime ihe ndị a bụ ihe mgbochi ọnụ ọgụgụ.Ọkpụkpọ ahụ dị na akara na poppet na valvụ enweghị ike ịrụ ọrụ.

Ihe kpatara valvụ ahụ mebiri site na irighiri ihe dị n'ime sistemu valvụ na-egbochi valvụ nlele na-eri nri na igwe na oche ọla.A na-enyocha ihe irighiri ihe na ihe ndị bụ isi na-egosi na ọ bụ ncha ígwè, ma eleghị anya na-emepụta n'oge ntinye nke eriri capillary.Tụkwasị na nke ahụ, a chọpụtara ụfọdụ ihe mkpofu na-acha ọcha na valvụ abụọ nlele karịsịa na azụ azụ nke valves.Nke a bụ akụkụ nrụgide dị ala, ya bụ, akụkụ ahụ ga-adị na kọntaktị mgbe niile na mmiri mmiri olulu mmiri.Na mbụ, a kwenyere na nke a bụ irighiri ihe sitere na olulu mmiri na-emepụta ebe ọ bụ na valvụ ndị ahụ mechiri emeghe ma kpughee ya na mmiri mmiri.Mana nyochaa irighiri ihe ndị ahụ gosiri na ọ bụ polymers nwere kemịkalụ yiri kemịkalụ a na-eji dị ka ihe mgbochi ọnụ ọgụgụ.Nke a dọtara mmasị anyị na Statoil chọrọ inyocha ihe kpatara irighiri ihe ndị a dị na eriri capillary.

Ntozu kemịkalụ

Na mpaghara HP HT enwere ọtụtụ ihe ịma aka gbasara nhọrọ kemịkalụ dabara adaba iji belata nsogbu mmepụta dị iche iche.Na ntozu nke onye na-egbochi ọnụ ọgụgụ maka injection downhole na-aga n'ihu, a na-eme ule ndị a:

● Nkwụsi ike ngwaahịa

● Okpomọkụ ịka nká

● Nnwale arụmọrụ dị ike

● Ndakọrịta na mmiri nhazi na hydrate inhibitor (MEG)

● Static na ike egbe eze ule

● Mgbasa ọzọ mmiri ozi, kemịkalụ ọhụrụ na MEG

A ga-agbanye kemịkalụ ahụ n'ọ̀tụ̀tụ̀ usoro ọgwụgwọ a kara aka,mana mmepụta mmiri agaghị abụcha mgbe niile,ya bu slugging mmiri.N'etiti slugs mmiri,mgbe kemịkalụ na-abanye n'olulu mmiri,a ga-ezute ya site na ọkụ,ngwa ngwa iyi nke hydrocarbon gas.Nke a dị ka ịgbanye ihe mgbochi ọnụ ọgụgụ na ngwa ebuli gas (Fleming etal.2003) .Together na

elu gas okpomọkụ,Ihe ize ndụ nke iwepụ ihe mgbaze dị oke elu na eze egbe nwere ike ime ka mgbochi nke valve injection.Nke a bụ ihe ize ndụ ọbụna maka kemịkalụ emepụtara na nnukwu ihe na-esi isi / obere vapor pressure solvents na ndị ọzọ Vapor Pressure Depressants(VPD's) .N'ọnọdụ nke mgbochi akụkụ.,eruba nke e guzobere mmiri,MEG na/ma ọ bụ kemịkalụ ọhụrụ ga-enwerịrị ike iwepụ ma ọ bụ gbarie kemịkalụ akpọnwụwo ma ọ bụ egbe gbapụrụ.

N'okwu a, e mere ụlọ nyocha ụlọ nyocha akwụkwọ akụkọ iji megharịa ọnọdụ na-asọ n'akụkụ ọdụ ụgbọ mmiri injection na HP/HTg dị ka usoro mmepụta.Nsonaazụ si na ike egbe eze ule na-egosi na n'okpuru chọrọ ngwa ọnọdụ a ịrịba ihe mgbaze ọnwụ e dekọrọ.Nke a nwere ike iduga eze egbe ngwa ngwa na igbochi okporo ụzọ.Ya mere, ọrụ ahụ gosipụtara na nnukwu ihe ize ndụ dị maka ịgba ọgwụ mgbochi mmiri na-aga n'ihu na olulu mmiri ndị a tupu mmepụta mmiri wee mee mkpebi iji dozie usoro mmalite mmalite maka ubi a, na-egbu oge ịgba ọgwụ mgbochi mmiri ruo mgbe achọpụtara mmiri.

The qualification nke ọnụ ọgụgụ inhibitor maka na-aga n'ihu injection downhole nwere nnukwu elekwasị anya na ihe mgbaze ịdọpụ na egbe eze nke ọnụ ọgụgụ inhibitor na injection point na na flowline ma ike maka egbe eze na injection valve n'onwe ya adịghị atụle.O nwere ike ịbụ na valvụ ịgba ntụtụ ahụ dara n'ihi nnukwu mfu ihe mgbaze na eze egbe ngwa ngwa,Fig.6. Nsonaazụ na-egosi na ọ dị mkpa inwe echiche zuru oke nke usoro ahụ;ọ bụghị naanị na-elekwasị anya na ihe ịma aka mmepụta,kamakwa ihe ịma aka ndị metụtara injection nke kemịkalụ,ya bụ valvụ injection.

Ahụmahụ sitere na ngalaba ndị ọzọ

Otu n'ime akụkọ mbụ na nsogbu na ogologo ahịrị ọgwụ injection chemical sitere na Gull fak sandVig dis satellite fields (Osa etal.2001). banye n'ahịrị site na valvụ injection.E mepụtara ụkpụrụ nduzi ọhụrụ maka mmepụta kemịkalụ n'okpuru oke osimiri.Ihe ndị a chọrọ gụnyere mwepụ (nyocha) yana mgbakwunye nke hydrate inhibitor (dịka ọmụmaatụ glycol) na ndị na-emechi ọnụ ọgụgụ mmiri niile ka a ga-agbanye na ndebiri subsea.Nkwụsi ike nke kemịkal,A tụlekwara viscosity na ndakọrịta (mmiri mmiri na ihe).Ebubala ihe ndị a n'ihu n'ime sistemu Statoil ma gụnye ọgwụ mgbochi ala.

N'oge mmepe na-adọ nke Oseberg S ma ọ bụ ubi e kpebiri na niile olulu mmiri ga-mechara na DHC m usoro (Fleming etal.2006) .Ebumnobi bụ igbochi CaCO.;nchicha n'ime tubing elu site na ịgba ogwu SI.Otu n'ime ihe ịma aka siri ike n'ihe gbasara ahịrị injection kemịkalụ bụ inweta nzikọrịta ozi n'etiti elu na mpụta ala.Dayameta dị n'ime nke ahịrị injection kemịkalụ dị warara site na 7mm ruo 0.7mm (ID) gburugburu valvụ nchekwa annulus n'ihi oke ohere na ikike nke mmiri mmiri a ga-ebufe site na ngalaba a emetụtala ọnụ ọgụgụ ịga nke ọma.Ọtụtụ olulu mmiri dị n'elu ikpo okwu nwere ahịrị injection kemịkalụ nke etinyere,ma a ghọtaghị ihe kpatara ya.Ụgbọ oloko nke mmiri dị iche iche (glycol,cruden,condensate,xylene,ihe mgbochi akpịrịkpa,mmiri wdg) ka a nwalere ụlọ nyocha maka viscosity na ndakọrịta ma na-ebugharị n'ihu na ntụgharị ihu iji mepee ahịrị.;Otú ọ dị,enweghị ike ịgbanye onye na-egbochi ihe nleba anya ruo na valvụ injection kemịkal.Ọzọkwa,nsogbu hụrụ na ọdịda nke phosphonate ọnụ ọgụgụ inhibitor ọnụ na residual CaCl z mmecha brine na otu olulu mmiri na egbe eze nke ọnụ ọgụgụ inhibitor n'ime a olulu mmiri na elu gasoil ruru na ala mmiri ịkpụ (Fleming etal.2006)

Ihe ndị a mụtara

Nnwale usoro mmepe

Isi ihe mmụta sitere na ọdịda nke sistemu DHC I bụ maka arụmọrụ teknụzụ nke ihe mgbochi ọ bụghị n'ihe gbasara arụmọrụ yana ntụtụ kemịkalụ.Ngwunye nke dị n'akụkụ na ntụtụ mmiri na-arụ ọrụ nke ọma karịa oge;Otú ọ dị,agbatịla ngwa ahụ na injection chemical downhole na-enweghị mmelite kwekọrọ na usoro ntozu kemịkal.Ahụmahụ Statoil sitere n'okwu ikpe abụọ ahụ ewepụtara bụ na a ga-emelite akwụkwọ na-achị achị ma ọ bụ ntụzịaka maka ntozu kemịkalụ iji tinye ụdị ngwa kemịkalụ a.Achọpụtara ihe ịma aka abụọ ndị bụ isi dị ka i) oghere n'ahịrị ntụtụ kemịkalụ na ii) enwere ike ịwụ mmiri mmiri.

Evaporation nke kemịkalụ nwere ike ime na mmepụta tubing (dị ka a na-ahụ na egbe eze ikpe) na na injection tubing (a transient interface ka achọpụtara na agụụ ikpe) e nwere ihe ize ndụ na ndị a precipitates nwere ike kpaliri na eruba na. n'ime valvụ injection wee banye n'olulu mmiri.A na-ahazi valvụ ịgba ntụtụ site na nzacha elu nke ebe ịgba ọgwụ,nke a bụ ihe ịma aka,dị ka ọ dị na mmiri ozuzo nwere ike itinye nzacha a na-eme ka valvụ ahụ daa.

Nleba anya na nkwubi okwu mbido sitere na nkuzi ndị a mụtara rụpụtara nnukwu ọmụmụ ụlọ nyocha gbasara ihe ndị a.Ebumnuche n'ozuzu ya bụ ịzụlite ụzọ ntozu ọhụrụ iji zere nsogbu ndị yiri ya n'ọdịnihu.N'ime ọmụmụ ihe a, emela ule dị iche iche ma chepụtakwa ụzọ ụlọ nyocha dị iche iche (mepụtara ka ọ) nyochaa kemịkalụ gbasara ihe ịma aka ndị achọpụtara.

● Nzacha mgbochi na nkwụsi ike ngwaahịa na sistemụ mechiri emechi.

● Mmetụta nke mfu ihe mgbaze na-adịghị mma na corrosivity nke kemịkalụ.

● Mmetụta nke mfu ihe mgbaze na-adị n'ime capillary na nhazi nke ihe siri ike ma ọ bụ viscous plọg.

N'oge ule nke ụzọ ụlọ nyocha, a chọpụtala ọtụtụ ihe nwere ike ime

● Ihe mgbochi nzacha ugboro ugboro yana nkwụsi ike adịghị mma.

● Akpụkpọ ahụ siri ike na-eso mkpọpu akụkụ ụfọdụ site na capillary

● PH na-agbanwe n'ihi mfu ihe mgbaze.

Ọdịdị nke ule ndị a na-eme nyekwara ozi ndị ọzọ na ihe ọmụma gbasara mgbanwe na njirimara anụ ahụ nke kemịkalụ n'ime capillaries mgbe etinyere ya n'ọnọdụ ụfọdụ.,na otú nke a si dị iche na nnukwu ngwọta doro ndị yiri ọnọdụ.Ọrụ nnwale ahụ achọpụtakwala nnukwu ọdịiche dị n'etiti nnukwu mmiri mmiri,akụkụ uzuoku na mmiri ndị fọdụrụnụ nke nwere ike iduga ma ọ bụ ụbara ike nke mmiri ozuzo na/ma ọ bụ ụbara corrosivity.

Emepụtara usoro ule maka corrosivity nke ndị na-emechi ọnụ ọgụgụ ma tinye ya na akwụkwọ nchịkwa.Maka ngwa nke ọ bụla, a ga-emerịrị nnwale corrosivity tupu etinyere ihe mgbochi ntụtụ.Emeela nnwale ndị eze egbe maka kemịkalụ dị n'ahịrị ịgba ọgwụ.

Tupu ịmalite iru eru nke kemịkalụ ọ dị mkpa ịmepụta oke ọrụ nke na-akọwa ihe ịma aka na ebumnuche nke kemịkal ahụ.Na nke mbụ, ọ dị mkpa ịchọpụta isi ihe ịma aka iji nwee ike ịhọrọ ụdị kemịkalụ ga-edozi nsogbu ahụ.Enwere ike ịchọta nchịkọta nke njirisi nnabata kacha mkpa na Tebụl 2.

Ikike nke kemịkalụ

Ikike nke kemịkalụ nwere ma nyocha na nyocha usoro maka ngwa ọ bụla.Ekwesịrị ịkọwapụta nkọwa teknụzụ na njirisi nnwale ma guzobe ya,dịka ọmụmaatụ n'ime HSE,ndakọrịta ihe,nkwụsi ike ngwaahịa na ịdị mma ngwaahịa (ụmụ irighiri ihe).Ọzọkwa,ebe kefriza,viscosity na ndakọrịta na kemịkalụ ndị ọzọ,hydrate inhibitor,ekwesịrị ikpebi mmiri na-emepụta mmiri na mmiri emepụtara.Enyere ndepụta ụzọ ule dị mfe nke enwere ike iji maka ntozu kemịkalụ na Tebụl 2.

Na-aga n'ihu na-elekwasị anya na nlekota oru nke oru ngo,Ọnụọgụ onunu ogwu na eziokwu HSE dị mkpa.Ihe achọrọ nke ngwaahịa nwere ike gbanwee ubi ma ọ bụ usoro ihe ọkụkụ n'oge ndụ ya;dịgasị iche na ọnụego mmepụta yana ihe mejupụtara mmiri.Ọrụ na-esochi na nyocha nke arụmọrụ,A ghaghị ime njikarịcha na/ma ọ bụ nyocha nke kemịkalụ ọhụrụ ugboro ugboro iji hụ na usoro ọgwụgwọ kacha mma.

Dabere na mma mmanụ,mmepụta mmiri na ihe ịma aka ọrụ aka na ụlọ ọrụ mmepụta nke dị n'ụsọ oké osimiri,ojiji nke kemịkalụ mmepụta nwere ike dị mkpa iji nweta mma mbupụ,usoro iwu chọrọ,na iji rụọ ọrụ nrụnye nke dị n'ụsọ mmiri n'ụzọ dị nchebe.Mpaghara niile nwere ihe ịma aka dị iche iche, na kemịkalụ mmepụta achọrọ ga-adịgasị iche site n'ọhịa ruo ubi na oge gafere.

Ọ dị mkpa ilekwasị anya na arụmọrụ teknụzụ nke mmepụta kemịkalụ na mmemme ntozu,mana ọ dịkwa oke mkpa ilekwasị anya na njirimara kemịkalụ,dị ka nkwụsi ike,àgwà ngwaahịa na ndakọrịta.Ndakọrịta na ntọala a pụtara ndakọrịta na mmiri mmiri,ihe na ihe ndị ọzọ na-emepụta kemịkalụ.Nke a nwere ike ịbụ ihe ịma aka.Ọ bụghị ihe na-achọsi ike iji kemịkal dozie nsogbu ka emechaa chọpụta na kemịkal na-enye aka ma ọ bụ na-emepụta ihe ịma aka ọhụrụ.O nwere ike ịbụ njirimara nke kemịkalụ ma ọ bụghị ihe ịma aka nka bụ ihe ịma aka kasịnụ.

Ihe achọrọ pụrụ iche

Ekwesịrị itinye ihe ndị pụrụ iche chọrọ maka nzacha ngwaahịa ndị a na-enye maka sistemu oke osimiri yana maka ịgbada ntụtụ na-aga n'ihu.Ekwesịrị ịnye ihe nzacha na ihe nzacha n'ime sistemu injection kemịkalụ dabere na nkọwapụta dị na akụrụngwa mgbada sitere na sistemu injection topside.,nfuli na injection valves,na downhole injection valves.Ebe downhole na-aga n'ihu injection nke kemịkalụ a na-etinye nkọwapụta na sistemu ọgwụ ọgwụ kwesịrị ịdabere na nkọwapụta nwere oke dị oke egwu.Nke a nwere ike ịbụ nzacha na valvụ injection downhole.

Ihe ịma aka injection

Usoro ịgba ntụtụ nwere ike ịpụta 3-50km nke eriri mmiri n'okpuru osimiri na 1-3km gbadaa n'olulu mmiri.Njirimara anụ ahụ dị ka viscosity na ikike ịkụnye kemịkalụ dị mkpa.Ọ bụrụ na viscosity dị na oke mmiri dị elu, ọ nwere ike bụrụ ihe ịma aka ịgbanye kemịkalụ ahụ site na ahịrị ịgba ọgwụ kemịkalụ dị n'akụkụ eriri mmiri nke dị n'okpuru mmiri na n'ebe injection subsea ma ọ bụ n'olulu mmiri.The viscosity kwesịrị dị ka usoro nkọwapụta na-atụ anya nchekwa ma ọ bụ arụ ọrụ okpomọkụ.Ekwesịrị ịtụle nke a n'ọnọdụ ọ bụla,ma ga-adabere na sistemụ.Dị ka tebụl kemikal ịgba ntụtụ bụ ihe na-eme ka ọ nwee ihe ịga nke ọma na ntụtụ kemịkal.Ka ibelata ihe ize ndụ dị n'itinye ahịrị injection kemịkal,kemịkalụ dị na sistemụ a kwesịrị igbochi hydrate (ọ bụrụ na enwere ike hydrates).Ndakọrịta na mmiri mmiri dị na sistemụ (mmiri nchekwa) na ihe mgbochi hydrate kwesịrị ịrụ ọrụ.Nnwale nkwụsi ike nke kemịkalụ n'ezie (okpomọkụ ikuku kacha dị ala enwere ike,ambient okpomọkụ,okpomọkụ subsea,okpomọkụ injection) ga-agafe.

A ga-atụlekwa mmemme maka ịsacha ahịrị injection kemịkalụ n'otu oge.Ọ nwere ike inye mmetụta mgbochi iji ihe mgbaze na-asacha ahịrị injection kemịkal mgbe niile,glycol ma ọ bụ kemịkalụ ihicha iji wepụ ihe nkwụnye ego ga-ekwe omume tupu akwakọba ya ma nwee ike ibute nkwụnye nke ahịrị.Ihe ngwọta kemịkalụ ahọpụtara nke mmiri na-agbapụta kwesịrị ịbụdakọtara na kemịkalụ dị n'ahịrị injection.

N'ọnọdụ ụfọdụ, a na-eji ahịrị injection kemịkalụ maka ọtụtụ ngwa kemịkalụ dabere na ihe ịma aka dị iche iche n'oge ndụ ubi yana ọnọdụ mmiri.N'oge mmepụta nke mbụ tupu mmiri ebute mmiri, ihe ịma aka ndị bụ isi nwere ike ịdị iche na nke ndị na-eme n'oge ndụ na-emetụtakarị mmepụta mmiri.Ịgbanwe site na ihe mgbaze na-abụghị nke mmiri dị ka asphalt ene inhibitor gaa na mmiri mmiri dị ka ihe mgbochi ọnụ ọgụgụ nwere ike inye ihe ịma aka na ndakọrịta.Ya mere ọ dị mkpa ilekwasị anya na ndakọrịta na ntozu na ojiji nke spacers mgbe a na-eme atụmatụ ịgbanwe kemịkalụ n'ahịrị injection kemịkal.

Akụrụngwa

Banyere ndakọrịta ihe,kemịkalụ niile kwesịrị ikwekọ na akara,elastomers,gaskets na ihe owuwu a na-eji eme ihe na usoro injection chemical na ụlọ mmepụta ihe.Ekwesịrị imepụta usoro nnwale maka corrosivity nke kemịkalụ (dịka onye na-egbochi ọnụ ọgụgụ acidic) maka mgbada ala na-aga n'ihu.Maka ngwa nke ọ bụla, a ga-emerịrị nnwale corrosivity tupu etinyere ọgwụ ogwu ogwu.

Mkparịta ụka

A ga-enyocharịrị uru na ọghọm dị na ntụtụ kemịkalụ downhole na-aga n'ihu.Na-aga n'ihu ịgbanye ihe mgbochi ọnụ ọgụgụ iji chebe DHS Vor tubing mmepụta bụ ụzọ mara mma iji chebe olulu mmiri site na ọnụ ọgụgụ.Dị ka e kwuru n'akwụkwọ a, e nwere ọtụtụ ihe ịma aka na-aga n'ihu na injection chemical downhole,Otú ọ dị iji belata ihe ize ndụ ọ dị mkpa ịghọta phenomena ejikọrọ na ngwọta.

Otu ụzọ isi belata ihe ize ndụ bụ ilekwasị anya na mmepe usoro ule.Tụnyere ntụtụ kemịkalụ dị n'akụkụ elu ma ọ bụ n'okpuru oke osimiri enwere ọnọdụ dị iche iche ma dị njọ karịa n'ime olulu mmiri ahụ.Usoro ntozu maka kemịkalụ maka ịgba ọgwụ na-aga n'ihu nke kemikal downhole kwesịrị iburu n'uche mgbanwe ndị a na ọnọdụ.A ga-emerịrị ntozu kemịkalụ dịka ihe kemịkalụ nwere ike ịbanye na kọntaktị siri dị.Ihe ndị a chọrọ maka ntozu na ule ndakọrịta n'ọnọdụ ndị na-emepụtaghachi dịka o kwere mee dị iche iche ọnọdụ ndụ ndụ nke ọma ga-arụ ọrụ na nke a ga-emelite ma mejuputa ya.Ekwesịrị ịmalite mmepe usoro ule n'ihu ka ọ bụrụ ule ezi uche na nke nnọchite anya.

Na mgbakwunye,mmekọrịta dị n'etiti kemịkalụ na akụrụngwa dị mkpa maka ịga nke ọma.Mmepe nke valves kemịkalụ injection kwesịrị iburu n'uche njirimara kemịkalụ na ebe ebe valvụ injection dị na olulu mmiri.Ekwesịrị ịtụle ya ịgụnye valvụ injection n'ezie dị ka akụkụ nke akụrụngwa nnwale na iji na-eme nnwale arụmọrụ nke ihe mgbochi ọnụ ọgụgụ na imepụta valve dị ka akụkụ nke mmemme ntozu.Iji tozuo oke inhibitors,Isi ihe lekwasịrị anya na mbụ bụ ihe ịma aka nke usoro na mgbochi oke,mana mmachi ọnụ ọgụgụ dị mma na-adabere na ntụtụ siri ike ma na-aga n'ihu.Enweghị ntụtụ kwụsiri ike na nke na-aga n'ihu, ikike nke nha ga-abawanye.Ọ bụrụ na valvụ inhibitor inhibitor valvụ bụ gunk ed ma ọ nweghị ihe mgbochi ihe mgbochi n'ime mmiri mmiri,A naghị echebe olulu mmiri na valvụ nchekwa site na ọnụ ọgụgụ ya mere enwere ike imebi mmepụta nchekwa.Usoro ntozu kwesịrị ilekọta ihe ịma aka ndị metụtara ịgba ọgwụ mgbochi ọnụ ọgụgụ na mgbakwunye na ihe ịma aka usoro na arụmọrụ nke onye na-eme ihe ruru eru.

Ụzọ ọhụrụ a gụnyere ọtụtụ ọzụzụ na imekọ ihe ọnụ n'etiti ọzụzụ na ọrụ dị iche iche ka a ga-akọwapụta.Na nke a ngwa na topside usoro usoro,ndebiri subsea na imewe nke ọma na mmecha na-esonye.Netwọk ịdọ aka ná ntị dị iche iche na-elekwasị anya n'ịmepụta ngwọta siri ike maka usoro injection chemical dị mkpa ma eleghị anya ụzọ isi gaa nke ọma.Mmekọrịta dị n'etiti ngalaba dị iche iche dị oke mkpa;karịsịa nkwurịta okwu chiri anya n'etiti ndị na-ahụ maka kemịkalụ bụ ndị na-achịkwa kemịkalụ etinyere na ndị injinia olulu mmiri bụ ndị na-achịkwa akụrụngwa eji na olulu mmiri dị mkpa.Ịghọta ihe ịma aka nke ngalaba dị iche iche na ịmụta ihe site na ibe ya dị mkpa iji ghọta mgbagwoju anya nke usoro ahụ dum.

Mmechi

● Inhibitor na-aga n'ihu n'ịgbanye ọnụ ọgụgụ iji chebe DHS Vor tubing mmepụta bụ ụzọ mara mma iji chebe olulu mmiri maka ọnụ ọgụgụ.

● Iji dozie ihe ịma aka ndị a chọpụtara,na-esonụ tụrụ aro bụ:

● A ga-emerịrị usoro ntozu DHCI raara onwe ya nye.

● Usoro ntozu maka valvụ injection kemịkal

● Nyocha na usoro ntozu maka ọrụ kemịkal

● Mmepe usoro

● Nnwale ihe dị mkpa

● Mmekọrịta ọtụtụ ọzụzụ ebe nkwurịta okwu n'etiti ọzụzụ dị iche iche metụtara dị oke mkpa maka ịga nke ọma.

Nkwenye

Onye ode akwụkwọ chọrọ ikele Statoil AS A maka ikike ibipụta ọrụ a yana Baker Hughes na Schlumberger maka ikwe ka ojiji onyonyo dị na Fig.2.

Nhọpụta

(Ba/Sr) SO4=barium/strontium sulfate

CaCO3 = calcium carbonate

DHCI= ogbugba kemịkalụ downhole

DHSV=valvụ nchekwa ala

eg=ọmụmaatụ

GOR=oke mmanụ ala

HSE= gburugburu nchekwa ahụike

HPHT=oke okpomọkụ dị elu

ID= dayameta ime

ya = ya bu

km=kilomita

mm = millimeter

MEG = mono ethylene glycol

mMD=mita tụrụ omimi

OD= dayameta dị n'èzí

SI= ihe mgbochi ọnụ ọgụgụ

mTV D=mita ngụkọta omimi kwụ ọtọ

U-tube=Ụkpụrụ U-tube

VPD= ihe na-ada mbà n'obi

Ọgụgụ 1. Nleba anya nke sistemu ogbugba kemịkalụ nke subsea na downhole na mpaghara atypical.Eserese nke injection kemịkalụ elu iyi DHSV na ihe ịma aka ndị metụtara ya tụrụ anya ya.DHS V = valvụ nchekwa downhole, PWV = valvụ nku usoro na PM V = valvụ njikwa usoro.

Onyonyo 2. Eserese nke sistemu ogbugba ogbugba mmiri nke ala na mandrel na valvụ.A na-ejikọta usoro ahụ na elu elu, na-eri nri site na-ma jikọọ ya na tubing hanga n'akụkụ anular nke tubing.A na-edobe mandrel ntụtụ kemịkalụ n'ime olulu mmiri n'ebumnobi inye nchebe kemịkal.

Onyonyo 3. Ọdịmma nke ọma mgbochi schematic,ebe agba anụnụ anụnụ na-anọchi anya envelopu nke ọma nke ọma;na nke a na mmepụta tubing.Agba uhie na-anọchi anya envelopu mgbochi nke abụọ;ihe mkpuchi ahụ.N'akụkụ aka ekpe ka a na-egosi ntụtụ kemịkalụ, ahịrị ojii nwere ntụ ntụ na-atụ aka na tubing mmepụta na mpaghara akara uhie (ihe mgbochi nke abụọ).

Ọgụgụ 4. Oghere oghere dị n'akụkụ elu nke ahịrị injection 3/8.E gosipụtara mpaghara ahụ n'ime eserese nke schematic nke ọma ihe mgbochi, nke ejiri ellipse oroma akara.

Ọgụgụ 5. Mwakpo corrosion siri ike na tubing Chrome 7" 3%.Ọnụọgụ a na-egosi mwakpo corrosion mgbe ihe mgbochi ọnụ ọgụgụ fesara site na ahịrị injection kemịkalụ gbagoro na tub nke mmepụta.

Ọgụgụ 6. Mpekere dị na valvụ injection kemịkalụ.Ihe irighiri ihe dị na nke a bụ ịkpụcha ígwè nwere ike ịbụ site na ntinye nrụnye na mgbakwunye na ụfọdụ irighiri ọcha.Nnyocha e mere n'ihe mkpofu ọcha bụ polymers nwere kemịkalụ yiri kemịkalụ a gbanyere

Oge nzipu: Eprel-27-2022